Welcome to

Starflex Bellows

on site Fabric bellow replacement

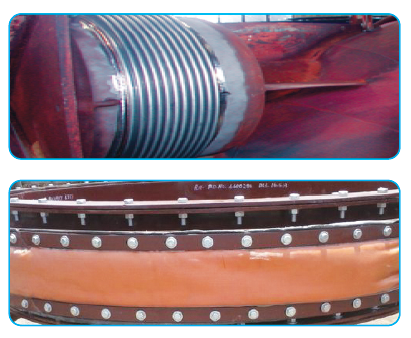

METALLIC EXPANSION BELLOWS

FABRIC BELLOWS

FRP - EXPANSION - JOINTS

DISMANTLING JOINTS

RUBBER EXPANSION BELLOWS

CLIENT SATISFACTION

With the firm to achieve maximum client satisfaction, we are offering a distinguished range of machines. Our on-time delivery, easy payment modes, client-centric approach.

INFRASTRUCTURE

Equipped with all the latest machinery and advanced tools, which assist us in offering a supreme quality range of products. optimum quality of raw material to meet international quality standards.

QUALITY ASSURANCE

we pay all our attention to providing optimum quality products. Highly acclaimed for his or her non-interrupted functionality, long functional life, and low maintenance.

on site Fabrics bellow replacement in Vadodara, on site Fabric bellows replacement in Baroda, on site Fabric bellow replacements in Gujarat, on site Fabric bellow replacement in India

on site Fabric bellow replacement by circumferential cracking resulting from cyclic bending stresses, or fatigue. Since the best on site Fabric bellows replacement in Baroda, between pressure strength and flexibility considerations, it can be concluded that their designs have had lower margins of safety regarding fatigue than they had regarding pressure strength. The years of experience of the engineers who developed these bellows assures that the designs contained during this catalog and people offered to satisfy customer specifications will have the performance reliability on site Fabrics bellow replacement in Vadodara. we are 24 hours service on-site fabrics bellow replacement in Vadodara. we are 24 hours service on-site fabrics bellow replacement in vadodara.

On site Fabric bellow replacements in Gujarat This conflicting need for thickness for pressure and thinness for flexibility is the unique design problem faced by the expansion joint designer. These premature failures usually are the result of one or more of the following causes on site Fabric bellow replacement in India.

On site Fabric bellow replacement

The insufficient margin of safety in the design permitting acceptance of a unit manufactured within a portion of the dimensional tolerance range to yield a part that will not satisfy the design. on site Fabrics, bellow replacement in Vadodara are extremely sensitive to changes in some dimensions, like the thickness and therefore the height of the convolution. These dimensional characteristics often affect the varied bending stresses by the square or cube of their differences. An understanding of these dimensional factors and how they can be controlled during design and manufacture is the on site Fabric bellows replacement in Baroda. The satrflex best service on site Fabrics bellows replacement in Baroda.

Poorly manufactured bellows or one that’s made to the “wrong” side of the dimensional tolerances will disappoint the simplest design and analysis. Bellows in clusters can be employed as robotic limbs, such as manipulator arms and legs for walking machines. For limb bending, analysis shows that there’s an optimal geometry for satellite bellows or a group of identical bellows clustered longitudinally a few central core. The satrflex best service on site Fabrics bellow replacement in India.

On site Fabric bellow replacements in Gujarat the bellows are clustered in a cylindrical helix whose angle is chosen to produce the desired on site Fabrics bellow replacement in Vadodara relationships, as an example the very best rotation for a given torque. For both bending and torsional limbs, experimental results are included that exhibit the predicted mechanical on site Fabric bellow replacement in India. The satrflex best service on site Fabrics bellow replacements in Gujarat.

A number of prototype tubular bellows were formed with the utilization of varied hydro forming die-shapes, like rectangular, circular, and triangular. For each shape, the formability of the tubular bellows, in conjunction with the forming process, was evaluated. The effect of friction was also investigated. Good lubrication is an efficient method for improving the hydro formability of metallic tubular bellows. The present study shows that a on site Fabric bellow replacements in Gujarat hydroforming process can be on site Fabric bellows replacement in Baroda. The satrflex best service on site Fabrics bellow replacement in India.

The expansion joint shouldn’t be expected to regulate the movement of the pipe. If the piping analysis shows that the expansion joint must accept on site Fabric bellow replacement in India, then the piping must be guided and constrained so that only that movement will occur. This expansion joint won’t resist any deflections with any force aside from the resistance of the bellows, which may be a function of the gimbal expansion joint manufacturers also on site Fabrics bellow replacement in Vadodara. The satrflex best service on site Fabrics bellow replacement in India.

on site Fabric bellow replacements in Gujarat of resisting the pressure thrust along its axis, which is the product of the pressure times the effective, or cross-sectional, area of the bellows. Large diameter units, even with low pressures, can generate large thrust forces, which must be reacted by main and directional anchors. Otherwise, the expansion joint will extend with disastrous results so on site Fabric bellows replacement in Baroda. The satrflex best service on site Fabrics bellows replacement in Baroda. The satrflex best service on site Fabrics bellow replacement in India.

Most engineered structures are designed to inhibit deflection when acted upon by outside forces. Since the bellows must accept deflections repetitively, and deflections result in stresses, these stresses must be kept as low as possible so that the repeated deflections will not result in premature fatigue failures. Reducing bending stress resulting from a given deflection is definitely achieved by simply reducing the thickness of the bending member, which within the case of the bellows, is that the convolution. on site Fabric bellow replacement in india, the convolution, which is also a pressure vesse gimbal expansion bellows.

Most bellows fail by circumferential resulting from cyclic bending stresses, or fatigue. Since the simplest design may be a compromise, or balance, between pressure strength and adaptability considerations, it are often concluded that their designs have had lower margins of safety regarding fatigue than they had regarding pressure strength. The years of experience of the engineers who developed these bellows assures that the designs contained during this catalog and people offered to satisfy customer specifications will have the performance reliability which yields trouble-free, safe use. on site Fabrics bellow replacement in Vadodara. The satrflex best service on site Fabrics bellow replacement in India.

The insufficient margin of safety in the design permitting acceptance of a unit manufactured within a portion of the dimensional tolerance range to yield a part which will not satisfy the design. Metallic bellows bending stresses are extremely sensitive to changes in some dimensions, such as the thickness and height of the convolution. These dimensional characteristics often affect the varied bending stresses by the square or cube of their differences. An understanding of these dimensional factors and how they can be controlled during design and manufacture is the on site Fabric bellows replacement in Baroda. The satrflex best service on site Fabrics bellow replacements in Gujarat.

Investigated herein is that the mechanical behavior of several pressurized bellows in clusters, which are designed to bend and twist also on extend and compress longitudinally. on site Fabric bellow replacements in Gujarat, such as manipulator arms and legs for walking machines. For limb bending, analysis shows that there’s an optimal geometry for satellite bellows or a group of identical bellows clustered longitudinally a few central core. For limb torsion, the bellows are clustered in a cylindrical helix whose angle is chosen to produce the desired gimbal expansion bellows. The satrflex best service on site Fabrics bellow replacements in Gujarat. The satrflex best service on site Fabrics bellow replacement in India.

A number of prototype tubular bellows were formed with the utilization of varied hydroforming die-shapes, like rectangular, circular, and triangular. For each shape, the hydro of the tubular bellows, in conjunction with the forming process, was evaluated. The effect of friction was also investigated. Good lubrication is an efficient method for improving the hydro formability of metallic tubular bellows. The satrflex best service on site Fabrics bellow replacement in Vadodara. The satrflex best service on site Fabrics bellow replacement in India. The satrflex best service on site Fabrics bellows replacement in Gujarat.

As experimental research, the effect of the environmental medium on corrosion fatigue life has been proposed in this paper. The research proves the very fact that the presence of a corrosive medium will accelerate both crack initiation and propagation rates and reduce the failure of life for the expansion joints. Furthermore, an important suggestion should be made that the effect of environmental medium on fatigue life must be paid more attention to when dealing on site Fabrics bellow replacement in Vadodara. The satrflex best service on site Fabrics bellow replacements in Gujarat. The satrflex best service on site Fabrics bellow replacement in India.

Address

14-Sanskar Tenament-2, Opp. Voltamp Transformers, Makarpura, Maneja, Vadodara-390 13. Gujarat, India.

Phone

+91-8153054857

+91 9825437991

starflexbellows@gmail.com

info@starflexbellows.in