Welcome to

Starflex Bellows

bellow element replacement

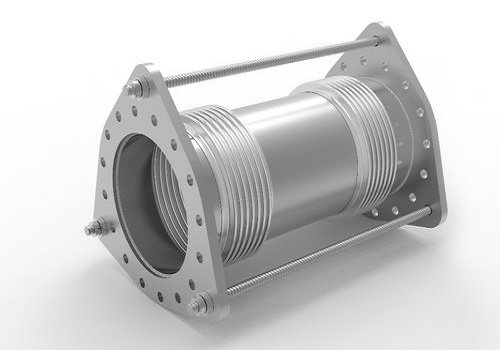

METALLIC EXPANSION BELLOWS

FABRIC BELLOWS

FRP - EXPANSION - JOINTS

DISMANTLING JOINTS

RUBBER EXPANSION BELLOWS

CLIENT SATISFACTION

With the firm to achieve maximum client satisfaction, we are offering a distinguished range of machines. Our on-time delivery, easy payment modes, client-centric approach.

INFRASTRUCTURE

Equipped with all the latest machinery and advanced tools, which assist us in offering a supreme quality range of products. optimum quality of raw material to meet international quality standards.

QUALITY ASSURANCE

we pay all our attention to providing optimum quality products. Highly acclaimed for his or her non-interrupted functionality, long functional life, and low maintenance.

bellow element replacement, bellows element replacement in vadodara, bellow elements replacement in baroda, bellow element replacements in gujarat, bellow element replacement in india

bellow element replacement is to be provided from the foundation to the top floor of the building. The one side of the expansion joint is first constructed to the desired level, then the Fiberboard is placed where the Expansion joint is to be provided then the other side is constructed. The fiberboard is sealed with sealing compounds. bellows element replacement in Vadodara.

if bellow elements replacement in Baroda is underway or even completed. This effect is to be expected bellow element replacements in Gujarat during the construction phase while variations during the design phase do not require any rework or demolition on construction sites so bellow element replacement in India.

bellow element replacement

bellows element replacement in vadodara will expand and contract due to the warming and cooling of our planet through the seasons. The structures would crack under the strain of thermal expansion and contraction if expansion joint gaps weren’t built into the structures. Even today the bellows element replacement in vadodara the design process, and simple caulking is used to fill these gaps to complete a project. This simple caulking cannot handle the thermal expansion due to the changing seasons bellow elements replacement in baroda.

bellow element replacements in gujarat of leakages in the structure which can ruin the interiors of the building if not sealed or treated confidently. bellow element replacement in india aspect of waterproofing design and detailing. In the former the joint has got to provide continuity of structural action between the members meeting at the joint. In the latter the joint has to ensure separation between the adjacent members to bellows element replacement in vadodara.

Variations often hinder the project progress, resulting in delay in achieving the targeted milestones during construction. Variations may bellow elements replacement in baroda delay the progress of the whole of the works or some part of it. The mere ordering of additional work as a variation of itself doesn’t import delay and consequent entitlement to an extension of your time but rather delay an activity or activities. Variations could also be on or off the critical path of the performance of the works. In these circumstances the Contractor may or bellow element replacements in gujarat.

A Gimbal Expansion Joint can accept bending or angulation in two planes. It contains two sets of hinge pins or pivots with the axis of each set perpendicular to the other. Each set of pins is connected to each other with a central gimbal ring, similar to an automobile universal joint.

In-line Pressure Balanced Expansion Joints consist of three bellows – two In-line bellows on each side and one balancing bellows in the middle. They are typically used when axial & lateral deflections exist

and anchoring is impractical for structural or economic reasons. An In-line Pressure Balanced Expansion Joint is a solution to difficult design problems.

Rectangular metal expansion joints are used for a variety of applications in power, petrochemical, refining, chemical, and steel industries. Due to the wide range of pressure, temperature, and duct size

requirements, each rectangular metal expansion joint is custom-engineered to provide an economical design that will not sacrifice the integrity of the entire system.

Type Expansion Joints are used to accommodate large axial movement. They are available in various materials for different temperature and pressure requirements. Design details must include

a selection of packing and sealing materials, as well as the media that flows through the expansion joint. All applications require machine surfaces to minimize abrasive wear. Others may require “wiper” mechanisms to prevent potential clogging between the two slipping pipes.

Address

Phone

+91 9825437991

info@starflexbellows.in